IT Technology Project

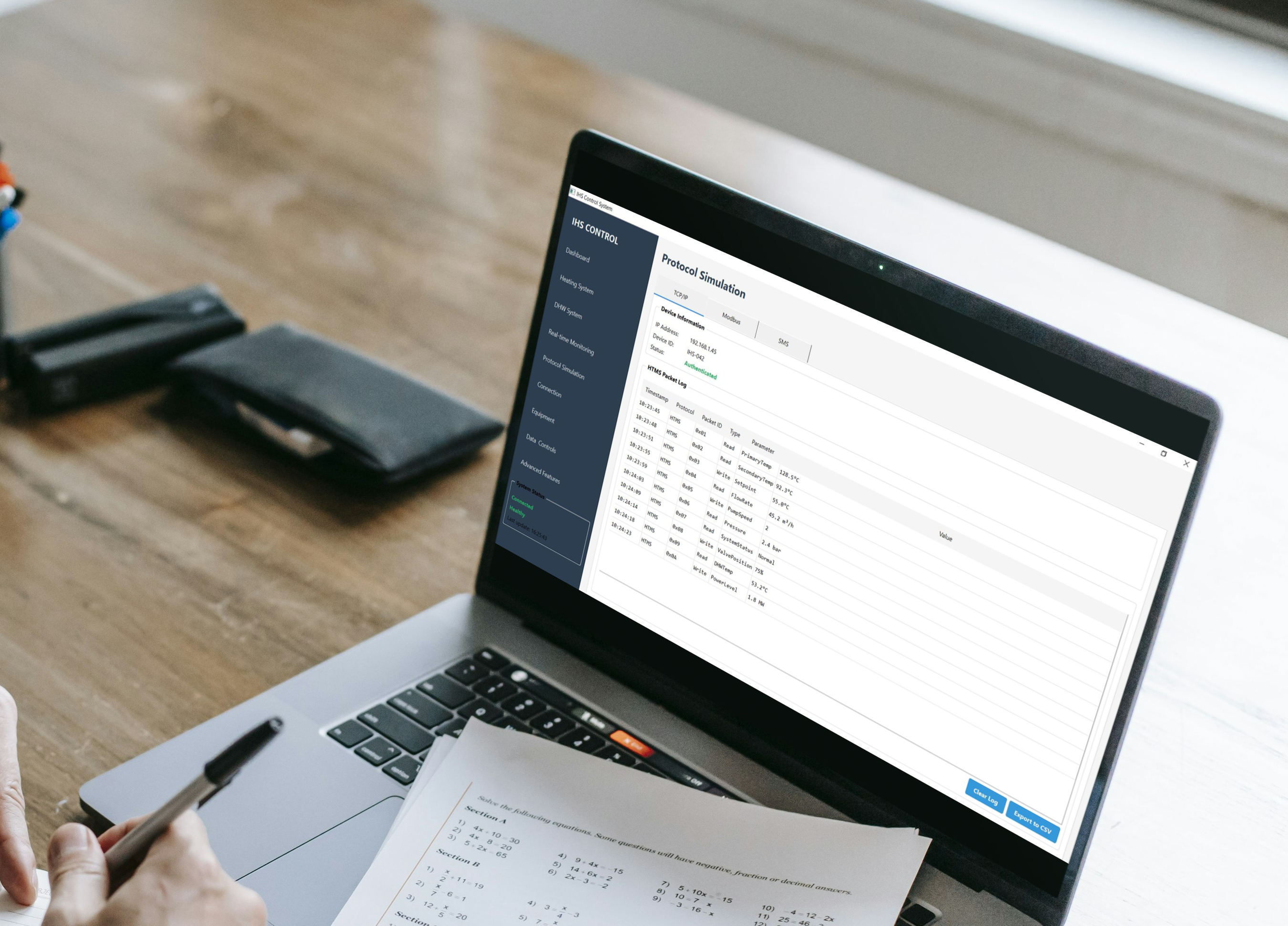

Protocol Simulation

The IHS Control System is a desktop-based graphical application designed to simulate and control district heating and domestic hot water (DHW) subsystems. The software replicates all key operational and diagnostic aspects of a physical IHS (Individual Heating Substation), and allows the users to interact with a virtual system that mimics real-time performance. The software interface consists of two main areas: A left-hand sidebar that provides navigation to all major pages. A main content area that changes based on the selected page

TCP/IP Simulation

- Shows HTMS protocol packet flow

- Each row shows timestamp, command type, and value (e.g., temperature read/write)

- Click "Export to CSV" for offline inspection

Modbus Simulation

Displays a list of simulated registers with address, parameter name, and value. Data types and access (Read-only or Read/Write) are indicated.

Domestic Hot Water System

DHW Temperature Setpoint and Control System for district heating management.

DHW Temperature Setpoint

- Adjust using the slider (40–70°C). The default is 55°C

- Below, the current measured temperature is displayed

Inlet/Outlet Temperature Cards

- Show temperatures at critical DHW points: Cold inlet (5°C), Hot outlet (53°C)

- Supply and Return from exchanger

Water Quality Indicators

- Automatically assesses Iron content, Oxygen level, and Suspended particles

- Status labels (Normal, High, Warning) are color-coded for quick evaluation

Recirculation Pump

- Shows pump status and last activation time

- Can be manually overridden if needed (checkbox)

Water Usage Panel

- Real-time flow rate in m³/h

- Accumulated usage (m³) for billing or efficiency review

Real Time Monitoring

This section controls and monitors the DHW side of the IHS.

DHW Temperature Setpoint

- Adjust using the slider (40–70°C). The default is 55°C

- Below, the current measured temperature is displayed

Inlet/Outlet Temperature Cards

- Show temperatures at critical DHW points: Cold inlet (5°C), Hot outlet (53°C)

- Supply and Return from exchanger

Water Quality Indicators

- Automatically assesses Iron content, Oxygen level, and Suspended particles

- Status labels (Normal, High, Warning) are color-coded for quick evaluation

Recirculation Pump

- Shows pump status and last activation time

- Can be manually overridden if needed (checkbox)

Water Usage Panel

- Real-time flow rate in m³/h

- Accumulated usage (m³) for billing or efficiency review

Heating System Control

Real-time Monitoring with interactive, zoomable charts that update each minute.

District Heating Circuit (Primary Side)

- Shows supply/return temps from central district supply

Building Heating Circuit (Secondary Side)

- Shows building loop temps

DHW Circuit

- Tracks DHW supply, return, and outlet temperatures

Temperature Differentials

- Delta T values showing system efficiency

Chart Analysis

- Each graph helps visualize temperature trends

- Can assist in diagnosing delays, imbalance, or misconfigurations